Advertisement

INTRODUCTION :

How To Make A Router Sled Table Machine :

A sliding router table is a very useful addition to any workshop. This project details the construction of a heavy-duty sliding router table, designed for precision routing, particularly for joinery like tenons, dadoes, and grooves on long workpieces. The key feature is the sliding sled mechanism, which uses linear bearings and smooth rods to ensure an incredibly smooth and accurate pass over the cutter.

Table Specifications

- Overall Dimensions (L x W x H): 60 in. x 28.5 in. x 30 in.

- Table Top Material: 20mm thick plywood (3 pieces).

- Frame Material: 1.5-inch square metal pipe.

Parts Used :

A. Frame and Table Top

- Frame:5-inch square metal pipes (for legs and supporting structure).

- Table Top: 3 pieces of 20mm thickness plywood, 60 inches long x 8.75 inches wide (Total width: 3 x 8.75 = 26.25 inches, plus gaps to reach \approx 28.5 inches).

- Router Base Plate: 10mm thick acrylic plate.

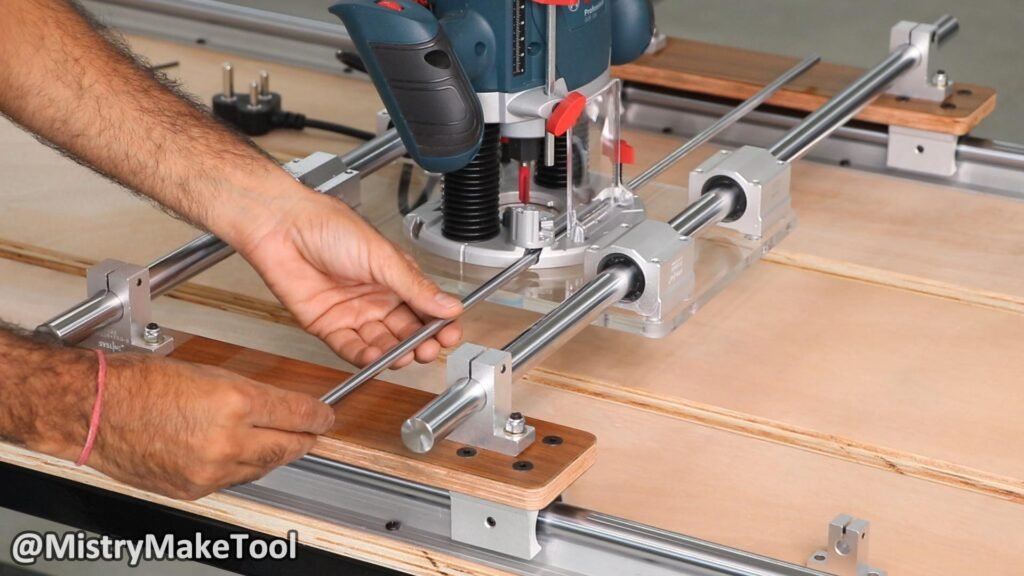

B. Sliding Mechanism (The Sled/Fence)

- Sliding Rails (Main): 20mm sliding rail smooth rod (Quantity: 2 for the main sled/fence motion).

- Linear Bearings (Main Sled/Fence):

- SBR20UU (Supported Block Bearing) – 4 Nos.

- SC20UU (Closed Block Bearing) – 4 Nos.

- Shaft Supports: SK20 (Shaft End Support) – 4 Nos.

- Bearing Support Plates: Two plywood plates (to attach the SBR20UU and SC20UU blocks to the sled).

C. Router Position Adjustment

- Router Position Rod: 8mm smooth rod.

- Router Supports: SK8 (Shaft End Support) – 2 Nos. (To hold the 8mm rod in a fixed position).

- Screws, nuts, and bolts

How to make :

Step 1: Construct the Metal Frame (Base)

- The frame provides the structural foundation and must be perfectly square and level.

- Cut the Metal Pipes: Cut the 5 inches square metal pipes to form a rectangular frame with outer dimensions of 60 inches (Length) by 28.5 inches (Width), and a height of 30 inches.

- Weld the Frame: Weld or bolt the pieces together. Ensure all corners are 90 degrees and the top surface is flat and level. Add cross-bracing for stability, especially on the long sides.

Step 2: Prepare the Plywood Tabletop Base

- I have used the three plywood pieces to form the fixed base of the table, created gaps for clamping.

- Position the Plywood: Place the three (60″ x 8.75″ x 20mm) plywood pieces onto the metal frame. The total width of the three pieces and the gaps should equal 5 inches.

- Determine Gaps: If the total width is 5 inches, and the three plywood pieces total 26.25 inches in width 3 x 8.75, you have 2.25 inches of gap space left. Then create two equal gaps of 1.125 inches each, or distribute them unevenly based on the clamping needs.

- Secure the Plywood: Screw the plywood pieces securely to the metal frame, maintaining the chosen gaps. This forms the fixed portion of the router table base.

Step 3: Install the 20mm Sliding Mechanism Rails (Fixed Side)

- This step involves mounting the linear rails and bearings to the table base and the two plywood support plates. This is the most critical step for smooth operation.

- First step is to attach the main 20mm 2 Nos. shaft rails of 59 inches length on the both sides of the table frame using screws.

- Prepare Plywood Plates: Cut the two thicker wooden plates to a size suitable for mounting the SBR20UU linear bearings and securing them to the underside of the fixed plywood base. These plates should span across the length needed for the sliding plate.

- Attach two SBR20UU bearings to each side of the sliding plate’s underside (four total). These bearings are designed to clamp onto the 20mm main sliding rail smooth rods.

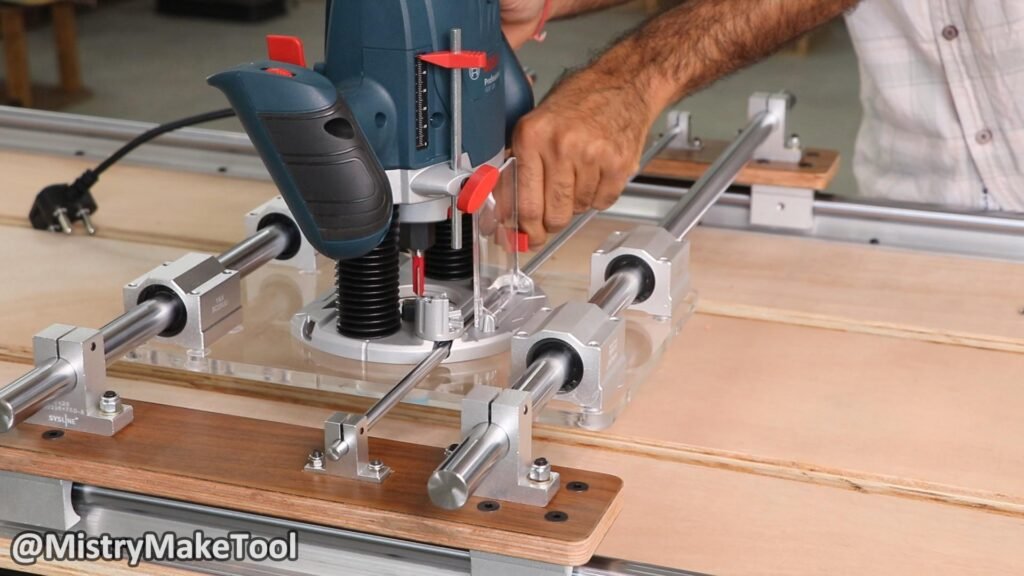

Step 4: Attach the acrylic plate base for router

- Cut the 10mm Thickness acrylic sheet in the dimension of 12” * 9” size. Cut a large circular opening in the center of the acrylic plate, large enough for the router bit.

- Drill holes on the plate according to the router and attach this plate on the router machine using screws.

- Mount the SC20UU Bearings: Attach four SC20UU bearings on the router base acrylic plate using screws, as shown in the image. These bearings will guide the sliding rod.

- Secure the SK20 Supports: Attach one SK20 shaft support near each end of the two wooden plates (four total). These will hold the ends of your 20mm smooth rods.

- Install the 20mm Smooth Rods: Insert the 20mm smooth rods into the SC20UU bearings and secure the ends into the SK20

Advertisement

- The two parallel 20mm smooth rods must be perfectly parallel to each other and the edge of the table. Use a straight edge and measure the distance between the rods at multiple points to confirm consistency. Any misalignment will cause binding.

Step 5: Mount to Router Base on Table

- Mount the router base on the table with the SC20UU linear bearing onto the 20mm smooth rod.

- Carefully place the router base sliding plate onto the 20mm smooth rods, ensuring the SC20UU bearings engage properly. The plate should slide back and forth with minimal effort. Adjust the parallelism of the fixed rods.

- Attach two SK8 shaft supports to the top surface of the main sliding plywood plates, in according to the router base 8mm hole for lock mechanism.

- Insert the 8mm smooth rods into the router lock mechanism and SK8 This allows the router to be adjusted across the width of the sliding plate.

- The screw mechanism is provided in the router machine to secure the router position with the help of 8mm smooth rod, as shown in the image.

- At last attach the L-angle supports at the ends of the two main sliding rails.

- The machine is ready to use. This machine is used to create slots in wooden workpieces and to flatten their surfaces.

For better understanding, Watch the video given below.

Advertisement