INTRODUCTION :

A chisel sharpening jig is often used to sharpening woodworking tools. Many of the tools used in woodworking have steel blades which are sharpened to a fine edge. A cutting edge is created on the blade at the point at which two surfaces of the blade meet. To create this cutting edge a bevel is formed on the blade, usually by grinding. This bevel is subsequently refined by honing until a satisfactorily sharp edge is created.

The purpose of the chisel sharpening jig is to hold the chisel or woodworking tool at the desired angle while grinding or honing the bevel. In some cases, the angle of the bevel is critical to the performance of the cutting edge—a jig allows for repeatability of this angle over a number of sharpening sessions.

There are many styles of jig available commercially. Fundamentally, all jigs are similar in that they allow the user to clamp the blade or tool in some way. The jig then has some means of referencing the clamped blade to the grinding or honing apparatus so that the bevel angle is maintained. One of the more common approaches is to have the jig ride on a roller. These types of jigs are usually used with a sharpening stone, such as a water stone, oilstone or diamond abrasive surface.

Here, I make a chisel sharpening jig from metal. This sharpening jig is strong because it is made from metal and it is used with sharpening stone.

Parts Used :

- Metal Piece 9”*3/4” (L*W) bend shape (5mm thickness)

- Metal piece 4.5”*1” (L*W) 6mm thickness

- 2 nos. bearings (bearing no. 6200-2RS)

- 2 nos. ¼ allenky bolts (1” length) with washers and fly nuts

- 2 nos. ¼ countersunk allenky bolts (12mm length)

- Sharpening stone

How to make :

First step is to cut 9” length metal piece of ¾” width and 5mm thickness, using angle grinder.

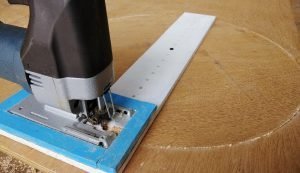

Next step is, bend both the end of the metal piece, using metal bender, as shown in the image.

Drill a hole on both the end of the bend part and make a ¼ thread, also drill a hole on both the side of the metal piece and make a ¼ thread using ¼ tape set, as shown in the image

Also drill a hole on both side of the metal piece of 4.5”*1” (L*W) 6mm thickness.

Paint and assemble all parts such as allenkey bolts, fly nuts, bearings, metal pieces etc, as shown in the image.

After that, make a groove on the plywood for sharpening stone, so the stone is fixed on the desired position.

Now, the sharpening jig is ready to use.

Some genuinely fantastic posts on this web site , thankyou for contribution. Kirbie Vin Ingra