INTRODUCTION :

Make A Hot Wire Foam Cutter:-

The hot wire foam cutter is a tool used to cut polystyrene foam and similar types of materials. The device consists of a thin metal wire, often made of stainless steel or nichrome, or a thicker wire preformed into a desired shape, which is heated via electrical resistance. As the wire is passed through the material (workpiece) to be cut, the heat from the wire vaporizes the material just in advance of contact. The depth of the cut of hot wire foam cutter is limited only by the wire length.

Hotwire foam cutting machines can use a vertical or a horizontal wire for cutting, usually with a horizontal table used as a guide or for securing the foam material. A foam cutter with a vertical wire is mainly used by hobbyists to cut small and complex shapes such as letters and others. Only prismatic members can be cut on this type of hot wire foam cutter.

Hotwire foam cutting machine with horizontal wires are heavily used in construction and packaging type work. The cutting hot wire is attached to tracks on either side of the table enabling it to be moved up and down making cuts very exact. This type of machine can also perform angular cuts.

A vertical or horizontal frame contains a set of evenly spaced parallel tensioned hot cutting wires. Massive blocks of foam are pushed through the frame on rollers, thus slicing them into sheets that are sold as “bead-boards” for general use in construction and packaging work etc. The blocks are guided so little skill is needed by the worker. The frame holding the cutting wires is often a replaceable and or adjustable unit so the spacing can be changed as per our requirements.

Cutting speed and hot wire temperature combine to determine the thickness and consistency of kerf. For a given hot wire temperature, an attempted motion over the wire’s ability to melt the foam material can lead to wire drag and poor surface finish of the cut foam. A non-uniform feed rate of the material can lead to a kerf of varying thickness.

Parts Used :

Plywood piece 20.5”*15” (10mm thickness) for the lower part

Plywood piece 20”*15” (10mm thickness) for the upper part

2 Plywood pieces 20.5”*2.25” (10mm thickness) for sidewalls

Plywood Piece 15”*(3”+1”) 1” extra part (10mm thickness) for backside

Plywood Piece 6”*5” (19mm thickness) used for round cut

Laminate sheet

Metal sheet 15”*3.5”

L-section aluminum channel 16” length with small metal pieces at the both ends (used as a fence)

2 nos. ¼ allenky bolts (12mm length) used for fence

Metal piece 23”*0.75” (5mm thickness)

Nichrome wire 32 gauge (length as per your requirement)

PWM controller with LED display

12v AC/DC power adapter

Female DC connector

Metal knob with 5/16 allenky bolt

Other bolts, nails, screws, and washer

Electric wire

4 nos. PVC knob for base

How to make :

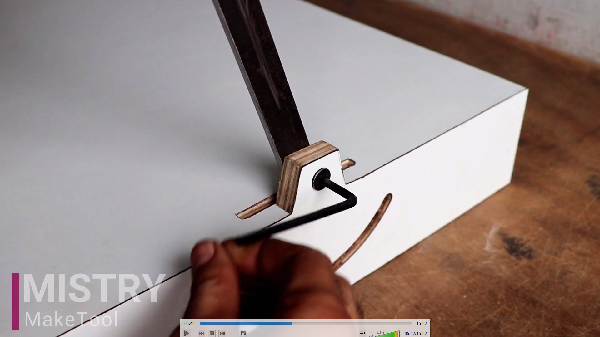

The first step is to cut the all plywood pieces in its desired dimension. Cut the internal side of the plywood piece 20.5”*15” (10mm thickness) for base, in the shape as shown in the image. I have used a jigsaw machine to cut this plywood. Also, cut the sidewall and other plywood parts.

Next cut the end of both sidewalls in taper shape using a circular saw crosscut.

Attach all plywood pieces as shown in the image, using glue and nails.

After this, laminate this table using of laminate sheet.

Make a slot on the table base and also on the backside of the table, as shown in the image. I have used a trimmer jig to cut this slot on the back wall plywood piece in half-round shape.

The next step is to bend the metal piece 23”*0.75” (5mm thickness) from the center by using of metal bender, and attach it with the table by using of 6mm countersunk allenky bolt.

Also attach the metal knob with 5/16 allenky bolt, as shown in the image.

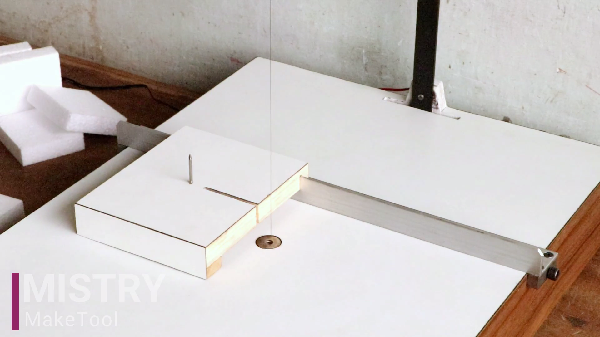

Drill a 6mm hole on the center of the table and also attach the 20mm diameter washer on it.

I have used a metal sheet of 15”*3.5” for the front side of the table. Cut the slot on this metal sheet for LED display, and attach it with a table on the front side by using screws.

Attach the PWM controller with an LED display on the metal sheet. Also, attach the female DC connector on the sidewall of the table.

Attach nichrome wire and all necessary electric wires with this. Also attach 4 nos. PVC knob for base.

I have used 12v AC/DC power adapter to give electric current to this foam cutter. Attach 12v AC/DC power adapter with a female DC connector. After the plug on the electric current is passed through this and the nichrome wire is getting hot. I can control the electric current using of PWM controller.

The next step is to make a fence. I have used L-section aluminum channel 16” length with small metal pieces at both ends to make a fence.

And at the last attach the plywood Piece 6”*5” (19mm thickness) on the workforce of the table. I make a slot on this plywood piece, and by using this slot and the fence, this plywood piece is moved parallel to the movable fence. With this plywood piece, I can cut the round shape.

Now, the hot wire foam cutting machine is ready to use.

Roti maker was so amazing, when it came to market for sales

Спасибо, давно искал

Wonderful article! We will be linking to this particularly great post on our website. Keep up the good writing. Maureen Galen Stutzman