INTRODUCTION :

The multi angle magnetic welding clamp is a great tool for welders. One of the biggest difficulty that welders face is positioning the items that need to be welded. That is where the magnetic welding square comes in use. The multi-angle magnetic welding clamps ensure that the items that require welding remain in position, greatly easing and improving the welding job.By using magnetic welding square welding productivity is increased.

Magnetic square allow user to simply stick a magnet onto the surface of the workpiece and start welding. Welding towards the middle of large structural, square, rectangular, or circular steel pipe becomes much more convenient. You only have so many hands and sometimes to achieve that perfect weld you need help. That’s where welding magnets and clamps come in to play. They can be used to create inside and outside corners as they can hold metal at a variety of different angles. Increase productivity, weld quality and reduce fatigue and be more efficient with magnetic welding square. These Welding Magnets hold items that need to be welded at 45° and 90° angles.

Parts Used :

- Sheet metal (2mm thickness)

- Speaker magnet (15mm thickness)

- Plywood

- 4mm screws (20mm length)

How to make :

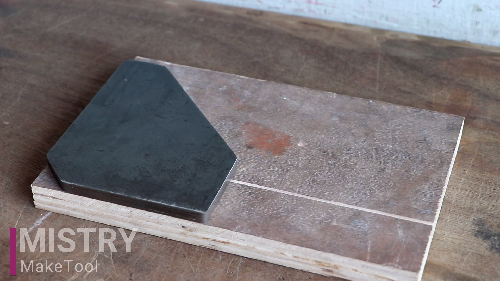

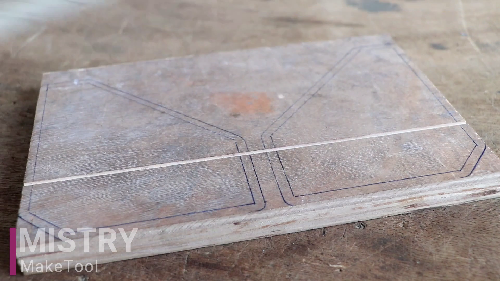

First step is cut the 2 pieces of metal sheet in to the shape of image shown by using of angle grinder. Dimension of sheet metal is 5”*4” (L*W) and 2mm thickness. Check the 45° and 90° anglesaccuracy by using of triangle square.

Second step is cut the plywood of same shape but slightly smaller than the metal sheet.

Drill a hole in the plywood of magnet diameter by hole saw cutter or by using of jigsaw for proper fitting of this magnet in to the plywood. I have used jigsaw table for this.

Also drill a hole in both the metal sheet of magnet hole diameter (32mm) by using of 32mm hole saw cutter.

Assemble all parts such as metal sheet, plywood and magnet by using of screws and nuts as shown in the image.

And at the last I painted this with red and black colors for batter look by using of spray paints. I make 2 nos. of these magnetic welding squares. Now, these magnetic welding squares are ready to use.

Advantages :

- Multi Angle Welding squares are used for fast and accurate welding or soldering work.

- Frees up the hands, making the welding job easier and more accurate.

- By using magnetic welding square welding productivity is increased.

- Reduce fatigue.