Let's See How To Make

INTRODUCTION :

Sharpening is the process of creating and refining a sharp edge of appropriate shape on a tool or implement designed for cutting operation. Sharpening is done by grinding away of material on the implement with an hard abrasive substance harder than the material of the implement. The substance on the sharpening surface of sharpening machine must be harder than the material being sharpened. Diamond is very hard material, so diamond wheel is very effective for sharpening of the tool.

Carbide saw blade is generally used for wood cutting operation. After long time of use of carbide saw blade, it will be required to sharpen the tooth of saw blade.

The saw blade sharpening machine is used to grinding and sharpening of carbide saw blades. There are many types of sharpening machine is available in the market, but cost of this types of machine is very high. So I decided to make a saw blade sharpening machine for my own. I have used 4” angle grinder machine to make it. For sharpening of the saw blade, I have used 4” glass cutter blade. The feed of saw blade towards the grinding wheel is done by hand. This sharpening of tooth for blades with a diameter of 4” to 8” is possible in this saw blade sharpening machine.

Material used :

- Black & decker 4” angle grinder

- Glass cutting blade

- Drawer slides (8” length) :-

- Drawer slides are a key component in a variety of different types, allowing drawer units and other things to move in and out in a fluid motion. Drawer slides are available in different styles and lengths as per our requirement. It is used in simple desk drawers to heavy duty tool storage drawers. I have used 8” long drawer slides to feed the saw blade towards the diamond glass cutter wheel.

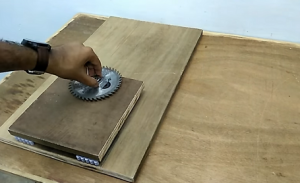

- Plywood sheet (18mm thickness) :-

- I have used 18mm thickness plywood sheet to make a base plate and upper plate of saw blade sharpening machine. The dimension of base plate is 22” * 13” and upper plate is 8” * 8”.

- Wooden block and clamps :-

- Wooden block support is used to support the angle grinder machine on the base plate and provide some height to the angle grinder. I have used two clamps to fix the angle grinder machine on the base plate.

- Bolt and AB washer :-

- Bolt and AB washer is used to attach the carbide saw blade on upper plate of sharpening machine.

- Screws :-

- Screws are used for attach the drawer slides and wooden block support on the base plate.

How to make :

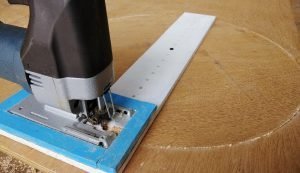

Step 1:- base plate and upper plate

First step is cutting the plywood sheet to make the base plate and upper plate. The base plate of 22” * 13” and upper plate of 8” * 8” cutting by table saw machine or circular saw machine. It is easy to cut by table saw machine.

Step 2:- Attach the drawer slides and upper plate

Second step is to attach the drawer slides with base plate and upper plate. I have used two drawer slides to move the upper plate in forward direction. It is move the upper plate in fluid motion and smoothly. Small screws are used to attach the drawer slides with base plate and upper plate.

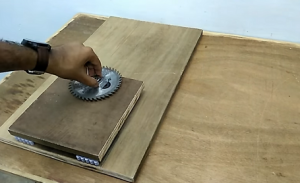

Step 3:- Bolt and AB washer

Third step is attach the bolt and AB washer to the upper plate, to attach the carbide saw blade on upper plate whose tooth are to be make sharp. So first of all drilling a hole to the upper plate and pass the bolt through this hole and after that attach the AB washer and carbide saw blade whose tooth are to be make sharp.

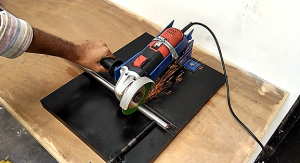

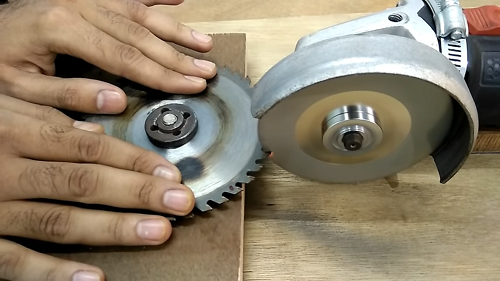

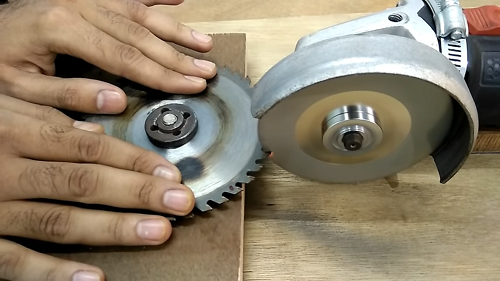

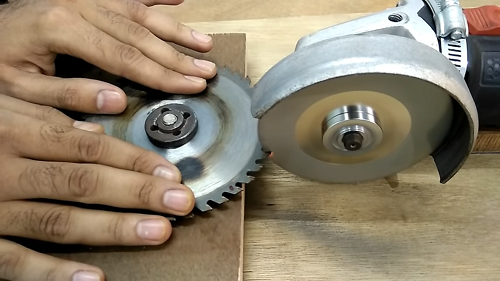

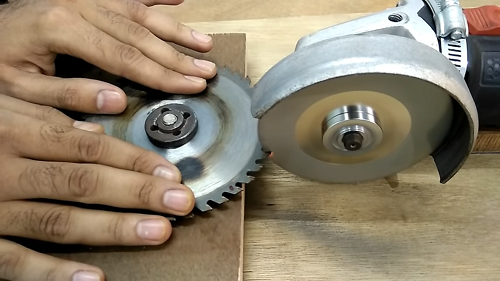

Step 4:- Fit the angle grinder on base plate in fixed position

Fourth and last step is fit the angle grinder in its fixed position on base plate. First of all attach the wooden block on base plate for support the angle grinder, than after fit the angle grinder on the wooden block by use of two clamps. Make sure that it has not any kind of movement between the angle grinder and base plate. Next step is attach, the glass cutting blade with an angle grinder. Now the saw blade sharpening machine is ready to use.

Advantages :

- Its cost is very less than what available in the market.

- Easy to sharpen the saw blade using this machine.

- Simple design and easy to make.