INTRODUCTION :

Angle grinders are standard equipment in metal workshop and on construction sites. Angle grinder stand is easy to make and very useful, made of metal, can still use it as a portable in seconds. I make a sliding angle grinder stand for my own use. Many people hold the Angle grinder on a Workshop Vice, and several times I have seen how they had to buy a new one, you can get to force the rotor or the brushes, disabling the tool, this sliding angle grinder stand will avoid that problem. In the market there are many types of accessories available for Angle grinder and they are useful for many jobs, this stand is fulfil all the purpose. Angle Grinder are dangerous tools, in this w ay you get more control is stand over them, but still, using all necessary protection such as goggles and gloves.

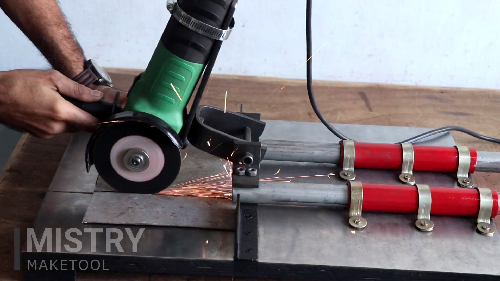

This angle grinder sliding cutting jig provide good accuracy for cutting metal parts, I knew doing it by hacksaw or even manually with the angle grinder would not yield the results I needed. A metal chop saw would have been perfect, but for long work piece cutting this was out of the question. So I considered a sliding stand for my angle grinder. I could have bought an off-the-shelf angle grinder stand, but I’ve had poor experiences of them in the past. This stand is something simple and easy to build and also provide accurate cuts. Also material that I have used to make this stand is also easily available. This sliding stand is for a small 4” angle grinder though you could apply this design to a larger grinder too.

Parts Used :

- Plywood sheet 14”*21” (18mm thickness)

- Sheet metal 14”*21”

- 2 Nos. galvanized pipes 1” (8” length)

- 2 Nos. galvanized pipes ¾” (20” length)

- Metal plate 5.25”*1.25” (6mm thickness)

- Band metal plate 10”*1.25” (6mm thickness)

- 1” L-section channel (14” length)

- 2 Nos. 1.25” L- section channels (1.25” length)

- Metal plate 8.5”*1.75” (5mm thickness)

- 6 Nos. pipe clamps

- 3/8” allenky bolt half thread (4” length) with lock nut

- 4 Nos. ¼” allenky bolts (20mm length) with nuts

- 2 Nos. 8mm allenky bolt (1” length)

- 10mm allenky bolt (1” length)

- Screws

How to make :

Step 1:- Make a base

This is the first step to make a siding angle grinder stand. I used 14”*21” plywood sheet and metal sheet to make a base. Sheet metal is attached on the plywood sheet by using of glue.

Step 2:- Attach galvanized pipe

I used 1” and 3/4” galvanized pipe for sliding purpose for this sliding angle grinder stand. First 1” galvanized pipes are attached on the base by using of pipe clamps and ¾” pipes are slide in 1” galvanized pipes.

Step 3:- Attachments of metal parts

Third step is attachments of metal parts. First attach the 5.25”*1.25” metal plate, L-section channel and band metal plate on the galvanized pipe by using of ¼” allenky bolts and nuts as shown in the image.

Then after, attach the 8.75”*1.75” metal plate on the band metal plate by using of 2 Nos. 8mm allenky bolts for angle grinder support as shown in the image.

Attach the rubber knob on the end of the galvanized pipes.

Step 4:- Attach the angle grinder

Fourth step, is attach the angle grinder. Angle grinder is attached on the angle grinder support plate by using of 10mm allenky bolts as shown in the image.

And the last attach the 1” L-section channel (14” length) on the base by using of screws.

After that I painted it with black and red colour. Now, the sliding angle grinder stand is ready to use. This is the useful homemade tool i have made, It makes my angle grinder much more functional and versatile.