INTRODUCTION :

How to make pipe bender :-

In this post, I show you how to make a pipe bender.

Pipe bending is any metal forming process used to permanently form pipes or tubing. Form bound bending procedures like “press bending” are used to form the workpiece into the shape of a die. Straight pipe stock can be formed using a bending machine to create different types of single or multiple bends and to shape the piece into the desired shape. These processes can be used to form complex shapes out of different types of metal pipes.

Pipe bending as a process starts with loading a pipe into a pipe bender and clamping it into place between two dies, the clamping block and the forming die. The pipe is also loosely held by two different dies, the wiper die and the pressure die. The process of pipe bending involves using mechanical force to push stock material pipe against a die, forcing the pipe to conform to the shape of the die. Stock tubing is held firmly in place while the end is rotated and rolled around the die and other forms of processing including pushing stock through rollers that bend it into a simple curve.

A pipe bender machine is used to bend a range of piping but most commonly; plumbing and conduit piping. Pipe bender is used to bend pipe in different directions and around obstacles instead of creating a fitting. To use a pipe bender, the worker pulls the handles of the pipe bender to force the pipe around the former. The pipe is sandwiched between the former and also the roller, so it is forced to take the former’s shape when pressure is exerted by the worker pushing the handles together.

In this post, I show you how to make a pipe bender. By using this pipe bender, the pipe is bending in two different diameters using two different diameter rollers.

Parts Used :

- Metal plate for base (10’”*8”) 10mm thickness

- Roller 127mm diameter (forming roller)

- Roller 85mm diameter (forming roller)

- Roller 65mm diameter (pressure roller)

- 2nos. metal plates to support rollers 1.5” width and 10.5” length (5mm thickness)

- 1.5 inch Square pipe 3.5” length to support handle

- 1.5 inch galvanized pipe for the handle (15” length)

- 1.5-inch L-section angle to support pipe (2.25” length)

- 14mm Allen key bolt with washers (3” length)

- ½” bolt with locknut with washers (3” length)

- 6 nos. 5/16 Allen key bolts for the handle (12mm length)

- 2 nos. 3/16 Allen key bolts (15mm length)

How to make :

The first step to make a pipe bender is to drill 14mm holes on both the metal plate (1.5” width, 10.5” length and 5mm thickness) to support a 127mm diameter forming roller, at the end of the metal plates.

The second step is to drill ½” holes on both the metal plate to support a 65mm diameter pressure roller.

Also, drill 14mm holes on both the metal plate for 85mm forming roller. The gaps between the two rollers depend on your requirements. In my case, there is a 1mm gap between the forming rollers and the pressure roller.

The next step is making a handle for pipe bender. I have used a 15” long galvanized pipe to make a handle. Also, I have used a 1.5-inch square pipe 3.5” length to support the handle.

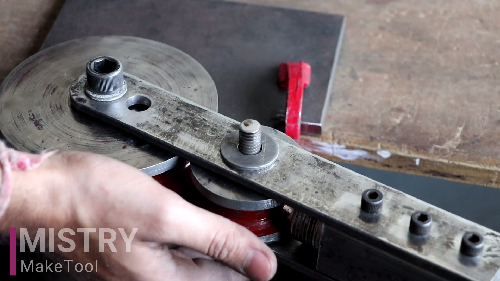

To make the handle, attach metal plates, square pipe, and galvanized pipe using of 6 nos. 5/16 Allen key bolts (12mm length), as shown in the image.

The next step is to make a base of the pipe bender. I have used a metal plate (10”*8”) 10mm thickness to make a base.

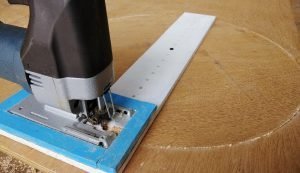

Drill 14mm holes for 127mm and 85mm forming rollers on the base plate and make a 14mm thread in these holes by using of 14mm tape set. Also, cut the base plate in the shape as shown in the image.

Now attach the forming roller, pressure roller, and handle with the base plate by using of 14mm Allen key bolt with washers and ½” bolt with locknut and washers, as shown in the image.

At the last attach 1.5-inch L-section angle to support pipe (2.25” length). Make a groove on the L-section angle, as shown in the image, and attach it with the base plate using of 2 nos. 3/16 Allen key bolts.

After that, I paint the pipe bender machine and the pipe bender is ready to use.

We require a pipe bender tool

Can you please provide?

Loving the information on this web site, you have done outstanding job on the content.

Pretty! This has been an extremely wonderful post. Thank you for supplying this information. Catlee Hoyt Lach

I am grateful to you for this beautiful content. I have included the content in my favorites list and will always wait for your new blog posts.