INTRODUCTION :

A drill press vice is a clamping device that is designed to be used in conjunction with a drill press. The vice is suited to being used with drill press due to its flat surface design. Drill press vice has a mounting holes which coincide with the mounting holes on the machine’s table. These holes allow bolts to be passed through in order to clamp the vice in place of table. The vice is mounted to the table of a drill press, and hold workpiece securely. It is used to clamp and position the workpiece during drilling operation.

This wooden drill press vice is useful in wood working workshop and it is also useful in metal working workshop. This wooden vice is simple, easy and quick to make. Its capacity of about 4” and is used with drill press and also on work bench. It can be used to hold variety of materials, including metal, plastic and wood. It can also be used for industrial work, as well as by home hobbyists and craftsman.

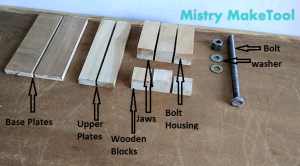

Material used :

- 12mm Bolt with nut ( 7’’ length )

- 6mm Bolt threaded at the end (2.5” length )

- Small washer of 8mm hole

- 2 Jaws( Fixed jaw and movable jaw ) and 1 Bolt housing (L*w*h=100mm*35mm*30mm)

- 2 Base plates of 12mm plywood ( 8” length and 2.25” width )

- 2 Upper plates of 15mm thickness (8” length and 1.25” width )

- Sliding guide block ( 35mm*35mm*12mm )

- 2 Wooden blocks for base plate support ( 35mm*35mm*26mm )

How to make :

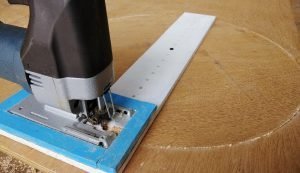

Step 1 :- Cutting parts

I have used 12mm plywood in base plate so first of all cut the plywood of 8’’ length and 2.25” width of 2 pieces. Now cut the upper plates of 15mm thickness of 8” length and 1.25” width. Then after, cut the jaws and bolt housing. This 2 jaws (movable jaw and fixed jaw) and bolt housing has same dimension of L*w*h = 100mm*35mm*30mm.

Step 2 :- Assembly of parts

Now after cutting all the required parts, I assembled all cutting parts. For assembly of parts I have used screws and glue. So here first assemble both the base plate and upper plate together by use of screws and glue. Then after fixed jaw and bolt housing are attached with upper plate by screw and glue. Also 2 supporting wooden block are attached with base plate.

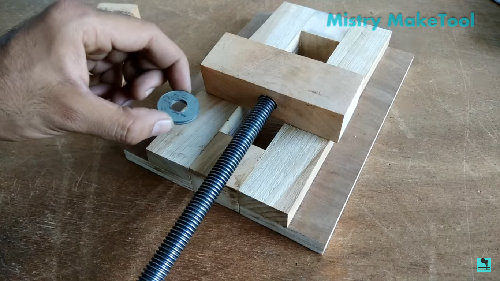

Step 3 :- Vice bolt and handle

I have used 12mm threaded bolt and make a slot at the end of bolt using angle grinder. Also cut the washer in middle and create two parts of it. Nut is fitted in the bolt housing, and after that pass the vice bolt through this nut. Now attach the end of the bolt with movable jaw by use of washer. Now it’s time to make a handle of the vice. Make a hole of 7mm diameter at the other end of the bolt, and after this the 6mm diameter and 2.5” long bolt is passed through this hole attached with it. So the vice bolt is easily turned with hand by use of this 2.5” bolt.

Step 3 :- Vice bolt and handle

Now it’s time to finishing the vice. I will use sanding paper to finishing. After finishing process, next step polishing. Polish on the vice is provides better look to the drill press vice. Now the drill press vice is ready to use.

Advantages :

- It is very simple, easy and quick to build.

- The cost of this vice is very less.

- Useful in both metal work and wood work.

- Light weight and simple construction.

Disadvantages :

- It is not strong as metal drill press vice.

- It is used for small and light weight product.

Application :

- Mostly preferred for wood working workshop.

- Small workshop of metal work.

- Automobile workshop.