INTRODUCTION :

Angle grinder is hand-held power tool and it is used for a huge variety of different job such as cutting, grinding, cleaning, polishing and finishing. Angle grinder is very useful power tool and now a, days use of angle grinder is increased. It is very dangerous to use without any safety equipment. Use of angle grinder stand is safe. Safety of worker is increased by use of angle grinder stand but it’s necessary to use safety equipment like goggles and gloves.

Its design and construction is very simple. There are many types of stand is available in the market but I decided to make it for my own use. This angle grinder stand is very useful in workshop of metal work and also of wood work. It is useful to cutting work piece accurately. This is the picture of my angle grinder stand. I have used 4” (820 W) black & decker angle grinder for my stand.

Parts Used :

- Metal base plate (18” * 13”)

- 3” C- Section channel angle 2 pieces of 7.5” and 3.5” length

- 1” L- Section channel angle 4 pieces (18” and 13” length)

- Door bracket 3”

- Hard spring 2” length

- Nuts and bolts

- Metal pieces

How to make :

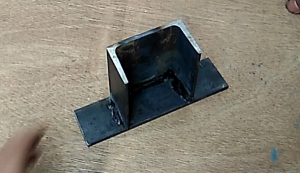

Step 1 :- Make a base of stand

First step of making of angle grinder stand is to make its base. This whole stand has been made from metal. The base plate of 18” * 13”and L-Section metal pieces are has been used to make the base. Required thickness of base plate is something 3mm for better performance of the stand. First of all cut the L-Section in four pieces equal to the four side of base plate. After that, weld the base plate and L-Section as shown in the image. Take care of that the weld is perfect and accurate.

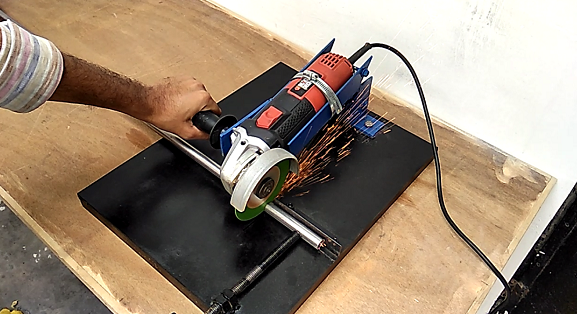

Step 2 :- C-Section for holding the angle grinder

In this stand I have used C-Section channel for holding the angle grinder. Angle grinder is perfectly fitted on it. Holding capacity of C-Section channel is very high then other section part and also strength is very good. Metal piece is weld with this C-Section to hold the angle grinder by bolt or handle of angle grinder. For easy and safe working handle is better to use. I have used handle of angle grinder so ease of grab grinder.

Step 3 :- Other part of C-Section

From the image you might have understood that how its make and what its purpose. Here first of all weld the metal piece at the end of C-Section like the image shown. Also drilling holes at the both side of metal piece for bolt.

Step 4 :- Attach both part of C-Section

Door bracket is used to attach the both part of C-Section. I have used 3” door bracket it is same as the width of C-Section. Make sure that the door bracket is of high quality and has no any type of play also load carrying capacity is high.

Step 5 :- Attach spring and whole assembly

Now this whole assembly is attached with the base by two bolts. Make sure that it has no any type of play between them. After this attach the spring. Then after two long size bolts fitted in the C-Section so the spring is attached between them like shown in the image. I have used 2” long spring you can also use two springs for better performance.

Step 6 :- Holding of work piece

It is the last step of making of angle grinder stand. I have used 7” long bolt and L-Section channel to make the holding device of work piece. Two Allen key bolts are used for attach the L-Section channel with base and then after the bolt with two nuts are weld with base as shown in the image. Now it’s ready to hold the work piece for cutting operation on stand. I have painted this stand for better look. Now it’s ready to use for cutting operation.

Advantages :

- Easy handling.

- Safety of worker is increased.

- More accurate cutting operation.

- Reduction in probability of injury caused by angle grinder.

- Fast cutting operation.

Application :

- Metal working workshop.

- Wood working workshop.

- At workplace.