INTRODUCTION :

A circular saw machine is a power tool for cutting many materials such as metal, wood, plastic, masonry and may be hand-held or mounted to a machine. In woodworking the term “circular saw” refers specifically to the hand-held type and the chop saw machine and table saw machine are other common forms of circular saws. Circular saw machines are indispensable power tools for making freehand cuts on a workshop or at jobsite, but their main drawback is a lack of accuracy when you need to make straight accurate cuts.

Circular saw tracks and guides are work great for cutting of plywood sheet, and typically you would turn to a miter saw for accurate and quick cutting smaller stock and trim. But if you don’t have a miter saw available, you can make a circular saw crosscut jig that will guide your circular saw in a straight line for making quick and accurate cuts. This homemade circular saw crosscut jig will add a precision cutting tool to your workshop at very little cost.

Parts Used :

- Plywood sheet 32”*18” (19mm thickness)

- 2 Nos. aluminium L-Section channels (32” length)

- 2 Nos. Wooden piece 1.75”*1.75” (15” length) for risers

- Wooden piece 32mm*32mm (11” length)

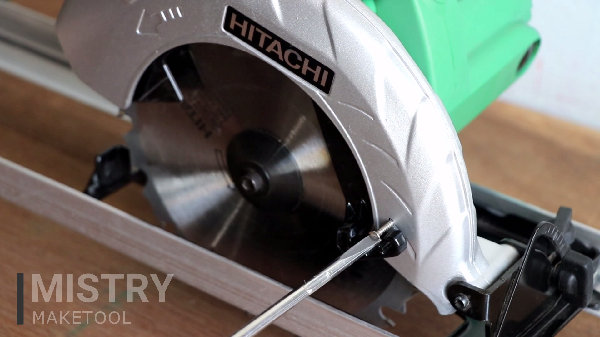

- Circular saw

- Screws

- 2 Nos. M6 fly bolts (half threaded) with nuts

How to make :

Step 1 :- Cutting of parts

First step to make circular saw cross cutting jig is cutting the Jig Base. The base of your jig can be at any size for you feel is necessary for your space. I used 19mm thickness plywood of 32”*18” for jig base. Also cutting the all parts required to make this jig of its desired dimension. Ensure the aluminium L-Section channels are straight and accurate. Both the L channels are of 32” length.

Step 2 :- Assembly of parts

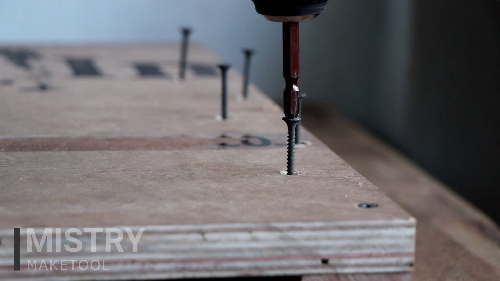

Next step is assembly of all cutting parts. First attach the risers. Apply wood glue to the bottom of the riser for better strength and check for squaring before using clamps to secure. Then, use screws to attach the riser to the base. Repeat the same process on the opposite side with the other riser, assuring that it is square.

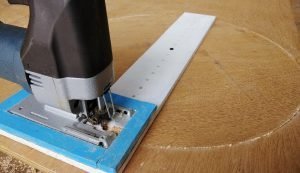

Place the both L-Section channels on the risers, and place the circular saw on top of the L channels to ensure the proper spacing. Drill a pilot hole through each end of the L channels and into the risers. You will want to countersink the screw holes so that the heads of the screws do not interfere with the circular saw. Screw the L channels onto place.

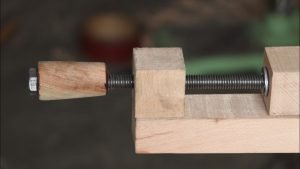

Also I made a work piece holder to accurately cut a 90° and 45° cuts. For this I used a wooden piece 32mm*32mm (11” length) and 2 Nos. M6 fly bolts (half threaded) with nuts.

Next to make a blade guard holder. I used a screw to fulfil this purpose and formed it to act as a stop. I make a hole and attach the bracket to the circular saw using a screw.

Step 3 :- Use and test cuts

I cut 2 pieces of wood, one at 45° and the other at 90° and attached them to 2 separate pieces of wood as shown, and check the accuracy of cutting wood by using of try square. It should be squared without any gaps.

As previously stated, this Circular Saw Crosscut Jig will prove to be a valuable addition to your shop. Hope you enjoy the versatility of this simple crosscut jig.